Get feedback

If you have any questions, you can leave us your contact e-mail - we will contact you as soon as possible.

By clicking on the button, you consent to the processing of your personal data.

21-st line V.O., building 2

Saint Petersburg

Saint Petersburg

PROJECTS

PROBLEMS OF THERMODYNAMIC, GAS CHEMICAL AND POWER PROCESSES OF OIL & GAS PRODUCTIONS

Development of scientific and methodological foundations for the design and creation of energy and gas chemical complexes to reduce the carbon footprint of the Arctic objects of the mineral resource complex of the Russian Federation.

READ MORE

PROBLEMS OF THERMODYNAMIC, GAS CHEMICAL AND POWER PROCESSES OF OIL & GAS PRODUCTIONS

OBJECTIVE:

development of scientific and methodological bases for the projecting and creation of energy and gas chemical complexes to reduce the carbon trace of Arctic objects of the mineral resource complex of the Russian Federation.

ACTUALITY:

Energy is the basement of the economy and the main driver of its development. In this regard, ensuring universal access to cheap, reliable, safe and environmentally friendly energy sources is one of the priorities in the context of global stable development.

Energy is the foundation of the economy and the main driver of its development.

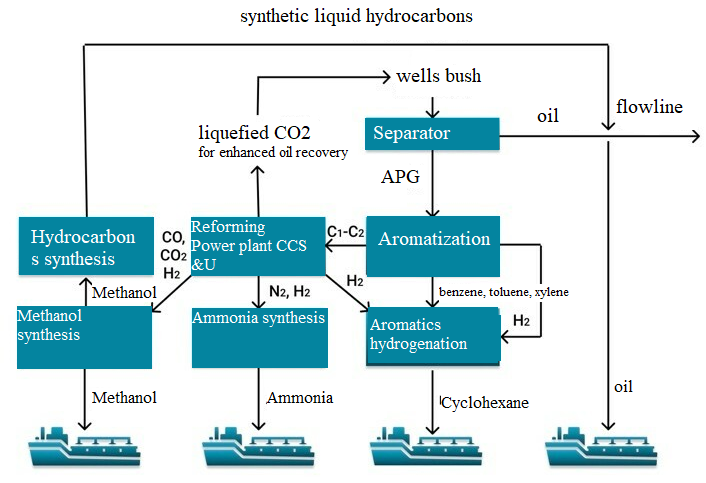

The concept of developing a remote Arctic oil and gas field with the possibility of producing and transporting blue hydrogen associated with methanol, ammonia and cyclohexane

This is directly indicated in the framework of the seventh UN objective and is indirectly traced in other sustainable development objectives, the achievement of which depends on the efficiency of the use (rational production and consumption) of natural resources, including raw materials.

The technologies developed within the framework of the scientific direction "Green Energy-underground space" are aimed at the rational use of natural resources and the reduction of the "carbon traces" from the production, transportation and use of oil and gas in order to ensure the stable development of the energy industry of the Russian Federation.

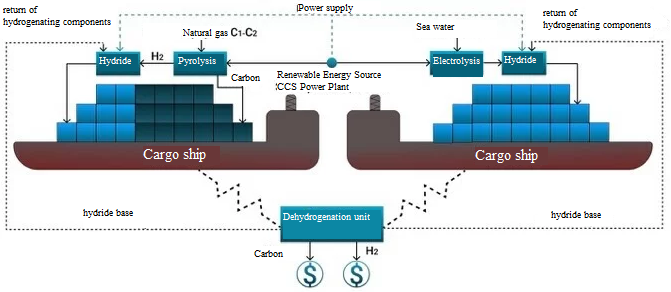

The concept of developing a remote Arctic gas field with the possibility of extracting and transporting solid carbon and turquoise hydrogen in the form of hydride using a dry cargo ship

1. The program of additional professional education "Complex utilization of associated petroleum gas in field conditions" has been developed and is being implemented.

2. The concept of "Gas-To-Chem" has been developed, which presents methods for increasing production efficiency through mutually complementary gas-chemical processes that provide flexibility in the supply of hydrogen and its derivatives by diversifying production.

3. An energy-efficient and eco-friendly technology for the utilization of associated petroleum gas has been developed. It is used in the conditions of oil fields, the degree of associated petroleum gas utilization at which can be brought to 100%. The technology combines a GTC (Gas-to-Chemical) process, a binary cycle, and CO2 capture.

4. A technological scheme for the production of "blue" hydrogen y non-catalytic autothermal reforming, followed by a catalytic reaction of water vapor, as well as the capture and liquefaction of carbon dioxide for its disposal, has been developed.

2. The concept of "Gas-To-Chem" has been developed, which presents methods for increasing production efficiency through mutually complementary gas-chemical processes that provide flexibility in the supply of hydrogen and its derivatives by diversifying production.

3. An energy-efficient and eco-friendly technology for the utilization of associated petroleum gas has been developed. It is used in the conditions of oil fields, the degree of associated petroleum gas utilization at which can be brought to 100%. The technology combines a GTC (Gas-to-Chemical) process, a binary cycle, and CO2 capture.

4. A technological scheme for the production of "blue" hydrogen y non-catalytic autothermal reforming, followed by a catalytic reaction of water vapor, as well as the capture and liquefaction of carbon dioxide for its disposal, has been developed.

The scientific direction includes the following departments and laboratories:

• Department of modeling and prototyping of processes and technological chains;

• Laboratory for testing catalytic and mass transfer processes;

• Laboratory for research of electrochemical processes and stress corrosion of metals.

• Department of modeling and prototyping of processes and technological chains;

• Laboratory for testing catalytic and mass transfer processes;

• Laboratory for research of electrochemical processes and stress corrosion of metals.

MAIN TARGETS:

• Comprehensive physical, mathematical and computer modeling, analysis of thermodynamic, gas chemical and energy processes of oil and gas production.

• Development of scientific foundations for the design and operation of new equipment to solve modern problems of oil and gas production.

• Conducting pinch analysis to minimize energy consumption by chemical and mass transfer processes and optimize the operating modes of oil and gas production.

• Conducting theoretical, prospecting, technological, laboratory and instrumental-bench studies for the purpose of rational subsoil use in the Arctic zone of the Russian Federation, including on the Arctic shelf.

• Development and testing of new methods and research programs in the field of thermodynamic, gas chemical and energy processes of oil and gas production.

• Development of scientific foundations for the design and operation of new equipment to solve modern problems of oil and gas production.

• Conducting pinch analysis to minimize energy consumption by chemical and mass transfer processes and optimize the operating modes of oil and gas production.

• Conducting theoretical, prospecting, technological, laboratory and instrumental-bench studies for the purpose of rational subsoil use in the Arctic zone of the Russian Federation, including on the Arctic shelf.

• Development and testing of new methods and research programs in the field of thermodynamic, gas chemical and energy processes of oil and gas production.

EXAMPLE OF RESEARCH:

DEVELOPMENT AND DRILLING OF WELLS IN THE ARCTIC

A multiple reduction in costs due to the replacement of dump sandy areas and sites with modular pile foundations, mounted in winter and providing year-round stationary pitless drilling of deep exploration and production wells in areas where unstable frozen soils and swamps are spread with the risk of seasonal flooding.

READ MORE

DEVELOPMENT AND DRILLING OF WELLS IN THE ARCTIC

OBJECTIVE:

multi-fold cost reduction due to the replacement of sand-filled areas and sites with modular stilt bases that are installed in winter and provide year-round steady-state tubeless drilling of deep exploration and production wells in the areas of unstable frozen soils and swamps with the risk of seasonal flooding.

ACTUALITY:

The development of reserves in the northern outlying territories, including the Arctic ones, is associated with a number of problems when drilling exploration and production wells.

The traditional technology of drilling equipment deployment implies a significant amount of preliminary work to fill the site, taking into account possible natural complications. The cost of such work increases due to non-compliance with the constructional norms of the fine-grained powdery sand used in the territories of the development objects.

The development of reserves in the northern outlying territories, including the Arctic ones, is associated with a number of problems when drilling exploration and production wells.

One of these problems is the construction of wells in the territories in the zone of permafrost distribution, which are subject to seasonal flooding.

Absence of an alternative to sand filling of the site leads to a significant increase in financial costs, which increase the total cost of construction of exploration wells. In addition, sand filling has both technological and environmental disadvantages, which cause a reduction in the service life of the fillable areas.

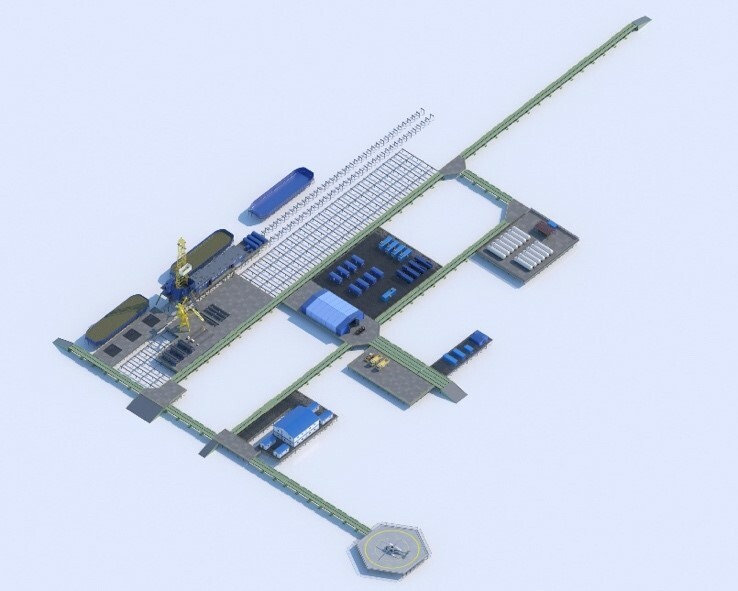

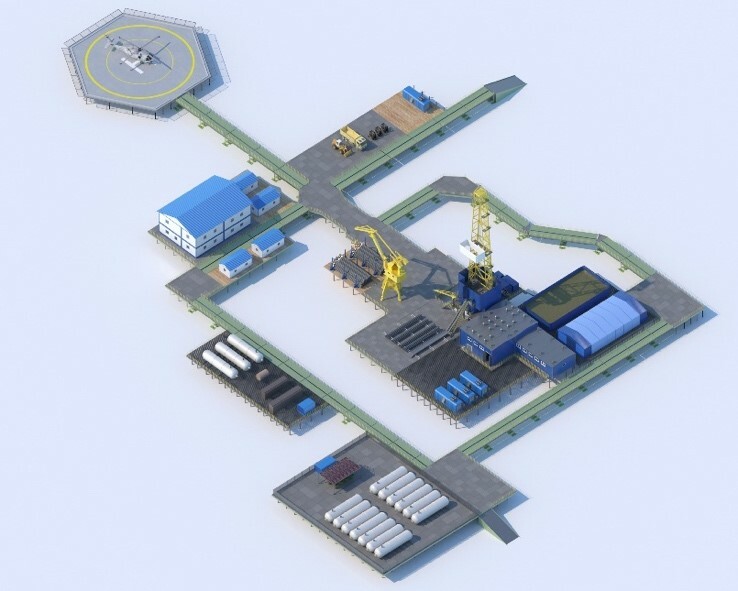

Modular base for drilling an exploration well from a drilling equipment

Modular base for operational drilling of wells from a drilling equipment

Based on the research and design studies carried out at the Mining University, it was determined that the cost of constructing modular stilt foundations is on average 50% less than the cost of organizing and maintaining sand deposits.

To verify the modeling results, it is planned to carry out full-scale tests of the load-bearing capacity of a single stilt foundation module with a load distributed on it in the conditions of seasonally flooded frozen soils in the coastal area of the Kara Sea. At the same moment, remote year-round monitoring of changes in the stress-strain state of modular stilt foundations is provided.

To verify the modeling results, it is planned to carry out full-scale tests of the load-bearing capacity of a single stilt foundation module with a load distributed on it in the conditions of seasonally flooded frozen soils in the coastal area of the Kara Sea. At the same moment, remote year-round monitoring of changes in the stress-strain state of modular stilt foundations is provided.

WELL CONSTRUCTION:

The scientific direction includes the following departments and laboratories:

• Department of equipment and technology for drilling and well workover;

• Well construction department;

• Laboratories «Drilling, technological fluids & cementing slurries»

• Well Drilling Technologies laboratory.

• Department of equipment and technology for drilling and well workover;

• Well construction department;

• Laboratories «Drilling, technological fluids & cementing slurries»

• Well Drilling Technologies laboratory.

MAIN TARGETS:

• Development of new types of special equipment and instruments for experimental and research work.

• Development of technologies, inhibitors and technical means to reduce hydrate formation during the operation of gas wells and the development of gas hydrate deposits;

• Development of technical and technological solutions for monitoring and controlling the parameters of drilling extended reach wells;

• Development of viscoelastic systems and technologies for isolating water-producing layers during drilling and workover of wells in gas and gas condensate fields;

• Development of technologies and technical means for efficient drilling of wells in difficult mining and geological conditions;

• Development of compositions of drilling fluids and destructors for opening layers with abnormal thermobaric conditions and well development technologies;

• Development of process fluids and technologies to improve the efficiency of hydrocarbon extraction;

• Development of process fluids to eliminate complications in the process of drilling wells.

• Development of technologies, inhibitors and technical means to reduce hydrate formation during the operation of gas wells and the development of gas hydrate deposits;

• Development of technical and technological solutions for monitoring and controlling the parameters of drilling extended reach wells;

• Development of viscoelastic systems and technologies for isolating water-producing layers during drilling and workover of wells in gas and gas condensate fields;

• Development of technologies and technical means for efficient drilling of wells in difficult mining and geological conditions;

• Development of compositions of drilling fluids and destructors for opening layers with abnormal thermobaric conditions and well development technologies;

• Development of process fluids and technologies to improve the efficiency of hydrocarbon extraction;

• Development of process fluids to eliminate complications in the process of drilling wells.

EXAMPLE OF RESEARCH:

OIL AND GAS DEVELOPMENT FACILITIES MANAGEMENT

Development of devices for preventing hydrate formation, which do not require energy supply from external sources and have sufficient reliability.

READ MORE

OIL AND GAS DEVELOPMENT FACILITIES MANAGEMENT

OBJECTIVE:

development of devices for preventing hydrate formation that do not require energy supply from external sources and have enough trustworthiness.

ACTUALITY:

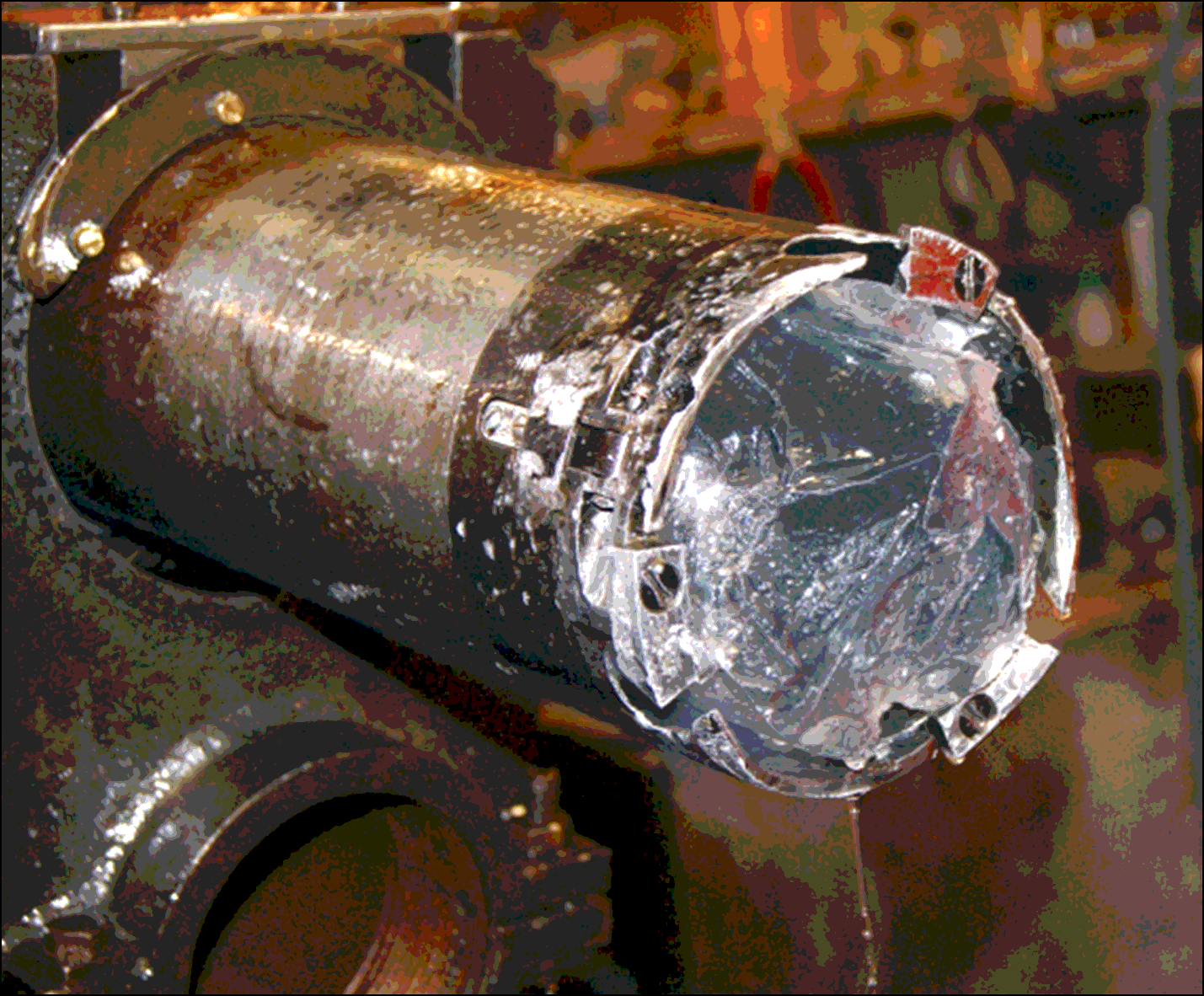

A general problem of gas production and its transportation through pipelines is hydrate formation. Hydrates are formed under certain thermobaric conditions, depending on the composition of the gas, and can prevent the functioning of wells and pipelines.

The problem of gas production and its transportation through pipelines is hydrate formation.

INJECTION OF METHANOL INTO THE WELL

Most often, hydrates are formed due to an extreme decrease in the temperature of the gas flow.

Dosing blocks are used to ensure the dosing of the supply of methanol to the downhole flow. Methyl is a strong cumulative poison, the delivery and use of which sometimes leads to a multiple increase in costs.

The requirement of the fields for methanol is estimated at 5-15 thousand tons per year (12 thousand tons per year for the Chayandinsky

Oil- and- gas condensate reservoir, which at a price of 43 thousand rubles per ton is about 500 million rubles per year).

Oil- and- gas condensate reservoir, which at a price of 43 thousand rubles per ton is about 500 million rubles per year).

GAS HEATING BEFORE REDUCTION AT THE GAS DISTRIBUTION STATION

Flow-through torch heaters are used, which use a part of the transported gas to generate heat.

The amount of gas for own needs is about 0.3 to 0.5% of the total pumping (for gas distribution station) of St. Petersburg and the Leningrad Region, this is 40.7 million m3 per year, or, at a price of 3470 rubles per thousand m3, 140 million rubles per year).

The scientific direction includes the following departments and laboratories:

• Department of geological and hydrodynamic modeling;

• Department of analysis and design of development of hydrocarbon deposits;

• Department of technology for complex preparation of gas and condensate for transportation;

• Department of pipeline networks and gas distribution systems;

• Department of technology for complex preparation of oil for transportation;

• Laboratory «Development of gas and gas condensate wells»;

• Laboratory «Core preparation and storage»;

• Laboratory «Increased oil and gas recovery of productive layers»;

• Laboratory for studying the properties of formation fluids.

• Department of geological and hydrodynamic modeling;

• Department of analysis and design of development of hydrocarbon deposits;

• Department of technology for complex preparation of gas and condensate for transportation;

• Department of pipeline networks and gas distribution systems;

• Department of technology for complex preparation of oil for transportation;

• Laboratory «Development of gas and gas condensate wells»;

• Laboratory «Core preparation and storage»;

• Laboratory «Increased oil and gas recovery of productive layers»;

• Laboratory for studying the properties of formation fluids.

MAIN TARGETS:

• Creation of mathematical geological and hydrodynamic models, models of ground gathering networks, preparation for transport and transportation of hydrocarbons. Development of new types of special equipment and instruments for experimental and research work.

• Conducting theoretical, prospecting, technological and instrumental-bench studies aimed at solving the problems of development and operation of oil and gas fields, transportation of hydrocarbons in the Arctic zone of the Russian Federation, including the Arctic offshore:

• Preparation of proposals for participation in promising research projects, programs, grants, including in the state assignment in accordance with the «Scientific directions of the Mining University of the world level»;

• Development of technologies and technical means (taking into account the use in water protection, nature protection and shelf zones) collection and preparation for transport, transportation of hydrocarbons, storage of gas in underground gas storages, LNG;

• Development and testing of new methods and research programs in the field of engineering and technologies for operating wells, infield equipment, systems for collecting and preparing gas, condensate and oil for transport, underground gas storage facilities, LNG fields in Arctic conditions.

• Conducting theoretical, prospecting, technological and instrumental-bench studies aimed at solving the problems of development and operation of oil and gas fields, transportation of hydrocarbons in the Arctic zone of the Russian Federation, including the Arctic offshore:

• Preparation of proposals for participation in promising research projects, programs, grants, including in the state assignment in accordance with the «Scientific directions of the Mining University of the world level»;

• Development of technologies and technical means (taking into account the use in water protection, nature protection and shelf zones) collection and preparation for transport, transportation of hydrocarbons, storage of gas in underground gas storages, LNG;

• Development and testing of new methods and research programs in the field of engineering and technologies for operating wells, infield equipment, systems for collecting and preparing gas, condensate and oil for transport, underground gas storage facilities, LNG fields in Arctic conditions.

EXAMPLE OF RESEARCH:

TECHNOLOGIES AND TECHNIQUES OF WELL DRILLING IN CONDITIONS OF VOSTOK STATION

Theoretical substantiation and experimental confirmation of new environmentally friendly technologies: deep drilling of wells in ice using drilling fluid, opening the subglacial Lake Vostok, studying the water column and bottom surface, sampling water and bottom sediments of Lake Vostok.

READ MORE

TECHNOLOGIES AND TECHNIQUES OF WELL DRILLING IN CONDITIONS OF VOSTOK STATION

HEAD OF THE DEPARTMENT:

Bolshunov Alexey Viktorovich

LEADING EXPERTS:

• Dmitriev Andrey Nikolaevich

• Blinov Pavel Alexandrovich

• Ignatiev Sergey Anatolyevich

• Evgeny Vitalievich Shishkin

• Blinov Pavel Alexandrovich

• Ignatiev Sergey Anatolyevich

• Evgeny Vitalievich Shishkin

PLANNED DEFENSE OF DOCTORAL DISSERTATIONS:

• Dmitriev Andrey Nikolaevich

• Blinov Pavel Alexandrovich

• Bolshunov Alexey Viktorovich

• Ignatiev Sergey Anatolyevich

• Blinov Pavel Alexandrovich

• Bolshunov Alexey Viktorovich

• Ignatiev Sergey Anatolyevich

PLANNED DEFENSE OF PHD THESES:

• Danil Vasilyevich Serbin

• Vasiliev Dmitry Alexandrovich

• Vasiliev Dmitry Alexandrovich

PROJECTS WITHIN THE LIMITS OF THE DIRECTION:

Event 21. "Comprehensive studies of the Earth's paleoclimate and subglacial Lake Vostok in the area of the Russian Antarctic station Vostok" as part of the implementation of the Strategy for the Development of the Russian Federation's Activities in Antarctica until 2030.

SCIENTIFIC NOVELTY:

Theoretical justification and experimental confirmation of new environmentally friendly technologies:

• deep drilling of wells in ice with the use of filling liquid;

• opening of the subglacial Lake Vostok;

• studies of the water column and bottom surface;

• sampling of water and bottom sediments of Lake Vostok.

• deep drilling of wells in ice with the use of filling liquid;

• opening of the subglacial Lake Vostok;

• studies of the water column and bottom surface;

• sampling of water and bottom sediments of Lake Vostok.

PRACTICAL RESULTS:

As part of the implementation of the event, the following will be carried out:

• creation of a new drilling complex for the Vostok station, including modern equipment for ice drilling;

• drilling of a new access well to Lake Vostok;

• opening of the subglacial Lake Vostok;

• preparation of the well for direct (in situ) studies of the lake water column, sampling of lake water and sediment samples;

• creation of modules for conducting direct studies of the water column and the bottom surface of the lake and technical devices for sampling water and bottom sediments.

• creation of a new drilling complex for the Vostok station, including modern equipment for ice drilling;

• drilling of a new access well to Lake Vostok;

• opening of the subglacial Lake Vostok;

• preparation of the well for direct (in situ) studies of the lake water column, sampling of lake water and sediment samples;

• creation of modules for conducting direct studies of the water column and the bottom surface of the lake and technical devices for sampling water and bottom sediments.

FUNDING:

The event is financed from the federal budget.

The amount of funding is 1,541. 6 million rubles.

The amount of funding is 1,541. 6 million rubles.

COLLABORATION:

The scientific direction includes the following departments:

•Department of technology and techniques for drilling wells in glaciers;

• Department of technology and techniques for research of subglacial reservoirs;

• Department of automation and monitoring of technological processes;

• Department of environmentally friendly filling liquids;

• Design and engineering department.

•Department of technology and techniques for drilling wells in glaciers;

• Department of technology and techniques for research of subglacial reservoirs;

• Department of automation and monitoring of technological processes;

• Department of environmentally friendly filling liquids;

• Design and engineering department.

MAIN TARGETS:

Conducting theoretical, exploratory, technological and hardware-bench research to develop new effective processes, methods, technologies and techniques aimed at:

• Development of environmentally friendly technologies for drilling wells in the conditions of Vostok station;

• Development of surface and downhole equipment for drilling wells in the conditions of Vostok station;

• Development of environmentally friendly technologies and technical means for penetration into the subglacial Lake Vostok, obtaining samples of lake water and samples of bottom sediments;

• Provision of scientific and technical support for drilling operations of the Russian Antarctic Expedition at Vostok station.

• Development of environmentally friendly technologies for drilling wells in the conditions of Vostok station;

• Development of surface and downhole equipment for drilling wells in the conditions of Vostok station;

• Development of environmentally friendly technologies and technical means for penetration into the subglacial Lake Vostok, obtaining samples of lake water and samples of bottom sediments;

• Provision of scientific and technical support for drilling operations of the Russian Antarctic Expedition at Vostok station.

EXAMPLE OF RESEARCH:

Do you have any questions or would you like to become a part of our team? Leave your question and contact information in the form below and representatives of the Scientific Center "Arctic" will contact you shortly By clicking on the button, you consent to the processing of your personal data |

Do you have any questions or would you like to become a part of our team?

Leave your question and contact information in the form below and representatives of the Scientific Center "Arctic" will contact you shortly

By clicking on the button, you consent to the processing of your personal data

© 2021 Scientific Center "Arctic"

SCIENTIFIC CENTER "ARCTIC"

The area and subject of the research center "Arctic" is the organization of scientific research to improve environmental safety and efficiency of development of existing fields, as well as the introduction of innovative approaches to new fields.

MAIN SECTIONS

CONTACT INFORMATION

Adress: 199106, Russia, 21st line V.O., 2

Saint Petersburg

Saint Petersburg

Telephone: +7 (812) 328-81-75